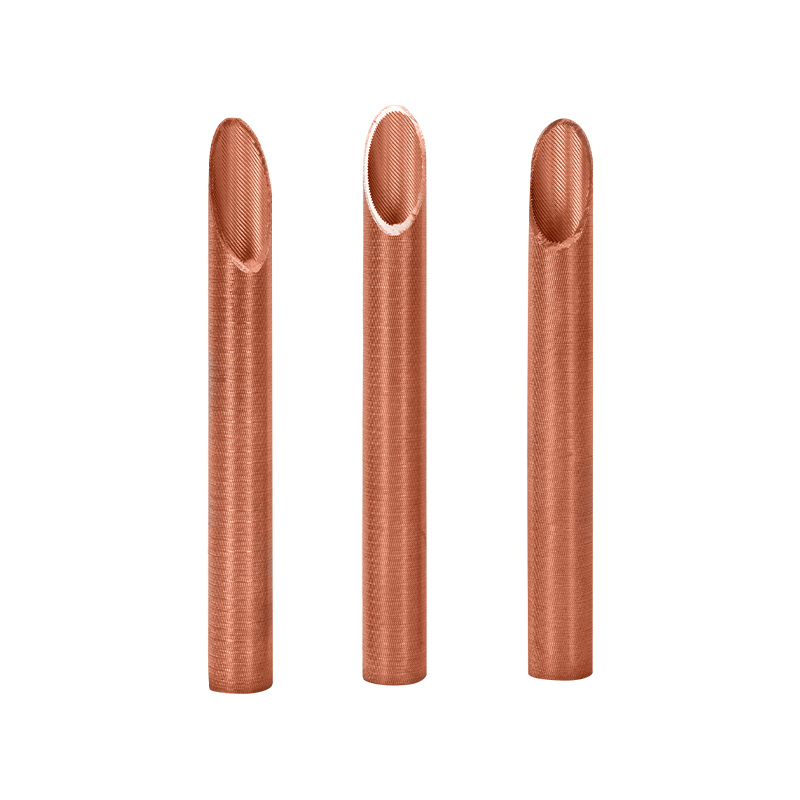

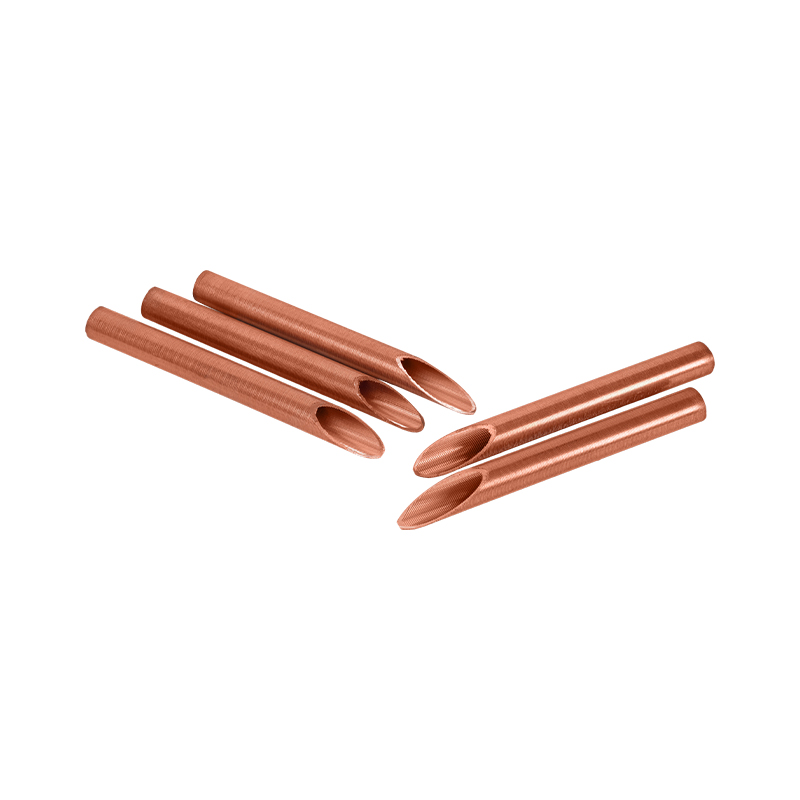

Aeris evaporator fistulam adoptat unique fin propositum et externae pinnulas instructa specialiter inter se internonected channels, ut inter se connectitur ad invicem ad formare completum liquidum superficiem. Hoc specialis structuram potest producendum numerus firmum vaporization nuclei in plenum liquorem evaporator, promovere crebris fluxus et evaporatio refrigerandi liquida in alveo, promovere continua release in refrigerandi bullae, et significantly augendae calor effectum. Quod calor translatione perficientur de aeris evaporator tubo est maxime, et calorem translationem coefficienti potest pervenire plus quam VII temporibus, quod Ordinarius Lux tubulis, vehementer improving ad efficientiam de system. In interiore muro tubi confortatus est minimize thermal resistentia interiorem murum et ut efficiens calor translatio. Et maximization ad Dual calor commutationem facultatem intra et extra facit aeris evaporator fistulam excellam in agro efficient evaporatio calor commutationem. Hoc productum est idoneam ad plenum liquorem evaporators magnam chillers ut Central Aeris-condiciones centrifugal unitatum et stupra machinis, et quoque late in testa et tuba calor in parvis temperatus differentia.

De nobis

30+Anni

Experientia

De nobis

A certa socium aeris tubo industria

Zhejiang Jingliang Copper-Tube Products Co., LtdStatutum in MCMXCIV, iam penitus involved in aeris tubo industria in tres decennia. In comitatu praesertim producere variis specifications productios ut aeris tubulis, aes tubulis, aeris quadratum tubulis, fin aeris tubulis, aeris, quae sunt et domestico et cum aeris et inquisita et cum exquirere et in Customers et Domestrie et internationali et inquisitionem et inquiram et exquirere et in Customers et Domestrie et PROCURATIVUS et exquirunt et in Customers et Domestrie et PROCURATIVUS et exquisita et domestica et acquirunt et inquisita et inquisita et in Customers et Domestrice et internationali.

Wide Applications:

Haec products sunt late in variis agros inter aerem condiciones, refrigeration, calor commutationem, sanitary ware, automotive, machinery, electrica fornaces et eget industria.

Convenient Translationem:

SUSCUS Sita in TangPu oppidum, clarus ut "domum aeris tubulis" in Oriente Sinis. Nostrum comitatu fruitur primi locus, adjacent ad Shangsan expressway et nationalibus via CIV, et commodius posita iustus super LXX chiliometrorum de Hangzhou et Ningbo, cursus facilis accessibility et Negotium.

Fortis Financial Resources:

Et fortis financial opibus et provectus aeris Tube processus technology, nostra turba tenet utile situ in foro participes, notam valorem, technica contentus, et uber qualis, becoming in malle elit pro multis enumerantur coetus.

Magna scale productio:

Company occupat an area super 20,000 quadratum metris, cum constructione area 12,800 quadratum metris. In MMXXII, nostris annua productionem exceditur 7,500 tons, cum valore output ad CDL decies Yuan, demonstrans fortis productio facultatem et foro aemulationem.

Comprehensive Industry torquem:

Jingliang iam developed in integrum industriae torquem integrationem odiosis, extrusionem, drawing, praecisione volubilem et annales. Hoc est consideratum plures honores, comprehendo "Top Decem Aeris Tube conatibus" et "ducens ADSIDUUS in aeris tubo industria".

Smert Manufacturing:

Jingliang aeris-tubo products mos melior integrate conceptum officinas constructione in suum corporatum progressionem belli, insist in conflans technology et politionem products magis subtiliter, et futurum est "intelligentes vestibulum."

Genuina cooperante:

Zhejiang Jingliang aeris-tubo products Co., Ltd benigne amicos ab omnibus ambulat vitae ad visit et offer ductu. Expectamus ad junctis manibus vobiscum ad creare egregie futura.

Technical artes

Processu productio

- I, electrolytic aeris

- II, aeris ingots

- III, torcular

- IV, drawing

- V, volvens

- VI, packaging

Electrolytic aeris, produci per electrolytic processuum, est summus puritas aeris cum bono electrica conductivity et scelerisque conductivity, faciens illud quod bonum materiam ad vestibulum aeris fistulae.

Hoc signa initium productio processus, quod involves fabricam electrolyticum aeris in pura aeris vel aes ingots secundum specifica processus et tractantem secans.

In pressione scaena, sectis aeris ingots premuntur in tenues laminas aut tubulosae figuris formatam initial tubulosam figuram et aeris sunt praeparati drawing et volvens.

Drawing est processus of longius processus aeris laminas et tubulosae obiecti, quae sunt pressed in requiritur dimensiones et figuras. Drawing aeris tubulis potest consequi praecisam exterius diametri murum crassitudines.

Rolling est gradus longius processus in aeris tubulis post drawing. Per volvens, in aeris tubos involutus in magis praecise dimensiones et figuras in occursum de requisitis diversis applications.

Denique aeris fistulae quae subruit volubilem erit packaged et paratus naviculas. Nos ut packaging est tutum et tutela ne damnum per translationem.

Nuntium

-

Copper tube Industry Segmentation Report: How Are Niche Markets Reshaping the Competitive Landscape?

Subtitulo: Dum tubulae aeneae traditae cum bellis pretiis opponunt, segmenta sicut semiconductor-gradus oxygenii liberi aeris tubularum et ultra tenues tubulae parietes novorum vehiculorum energ...

PLURA LEGE -

In mundo calor *is nummularii, systemata caeli condiciones, refrigerationes unitates, aliaque applicationes administrationis thermarum, electio materiarum fistularum quae calor facilior translatio ...

PLURA LEGE -

Systema refrigerationis essentialia sunt in hodierna vita, a conservatione cibi et medicinae ad consolationem nostror *um domorum et operum conserveta. Una e elementis praecipuis quae harum systema...

PLURA LEGE -

Subtitle: Cum US L% portoriis in tubulis aeneis imposuit catenam commercii globalis reficiendi, quomodo capacitas productionis in Asia Meridiana et Mexici ab 46,3% intra annum assurgat? Copia hu...

PLURA LEGE -

Subtitle: Quomodo Tubulares Conductores cavum in Energy Systems Efficientiam Redefining, dum Traditional Solutiones Grapple cum Space et euismod limitationes. Technological Transformation...

PLURA LEGE

Industria scientia

Comparari aluminium fistulae quid commoda et incommoda aeris evapurator fistulae?

Technical commoda aeris evaporator tubulis

I. Optimum scelerisque

De scelerisque conductivity of aeris est de CCCXCVII w / (m K + k), quod significantly altior quam de Aluminium, de CCXXXVII w / (m · k), quod est quod sub eadem calore in refrigerator cito et efficaciter. Hoc est maxime momenti in industria, salvis aer conditioners, industriae refrigerationem et summus efficientiam calorem sentinam systems.

II. Superiore fortitudinem et pressura resistentia

Aeris materiae habere altiorem mechanica vires, praesertim in tenuis-muratam pipe consilia, possunt melius resistere impulsum summus pressura refrigeribus et non proni ad crepuit vel deformatio. Hoc pluma facit aeris evaporator tubi magis idoneam ad novam generatio summus pressura environmentally amica refrigerare (ut r410a, co ^ etc.) systems.

III. Optimum corrosio resistentia et servitium vitae

Aeris habet naturalem oxidatio resistentia et pitting resistentiam, et potest ponere firmum perficientur in umida et mordendo environments. Praesertim in missionibus ut seaside, industriae areas vel usura sal aqua refrigerationem systems, aeris evaporator tubi Monstra meliora vita polliceri.

IV. Facilis dispensando et diversificatur structural consilium

Aeris fistulae boni ductility et formability, et potest processionaliter in universa structurae ut internum fila est tubi, plana fistulae, fined aeris tubulis, etc, ad optimize exiguam exchafy Zhejiang Jingliang aeris, tubo products Co., Ltd diu focused in productionem summus perficientur internum costa aeris et subtilissimum aeris capillarium.

V. reusable, environmentally amica et recyclable

Aeris est princeps redivivus valorem et fortis reusability. Hoc est in linea cum current trend of virens vestibulum et sustineri progressionem sub "Dual ipsum" belli, et quoque unum ex causa quod multi developed terris in Europam et Civitatum Foederatis Americae.

Potential incommoda aeris evaporator tubulis

Licet aeris habet multa commoda, quod etiam habet quaedam limitations in certis missionibus et sumptus-repulsi:

I. relative alta materia sumptus

Aeris prices fluctuare vehementer et altiore pretium solet altior aluminium. Nam humilis-finem foro, quod persequitur sumptus imperium, ut quidam low- et medium-finem familia aer conditioners et refrigerator products, aluminium habet quaedam appellatio.

II. Gravis pondus

Et densitate aeris est 8.96 g / CM³, quod significantly altior quam 2.70 g / CM³ aluminium. In areas cum stricte pondus requisita (ut automotive aer condiciones et aviation systems), aluminium tubi potest reducere altiore onus de system et amplio industria efficientiam.

III. Quod nexum processus est magis complicated

Licet aeris tubos habent bonum welding perficientur, in aliquo automated productio lineas, in bracchia aeris ex aeris tubulis est leviter incommodum in terms of sumptus et efficientiam comparari cum mechanica expansion processum aluminium aluminium. Tamen hoc problema est per gradus solvitur per continua technicae upgrades conatibus ut Zhejiang Jingliang in intelligentes vestibulum.

Quid est communis defectus et imperium mensuras superiores aeris evapurator fistulae in Welding processus?

Communis defectibus in Welding processus of aeris evaporator tubi

I. Porosity

Porosity est maxime communis problems in aeris tubo welding, solet per oleum, humorem, oxides aut impurus protegens Gas in Welding regio. Hi minima foramina non infirmare in airthirness de weld et afficit pressura resistentia et servitium vitae evapormator.

II. Nullam eget

Haec defectus manifestatur ut imperfecta vinculum inter basis materia et solidatur, solet per insufficiens welding temperatus, inaequaliter calefacit aut impropria operatio. Nullam fusionem faciam structurae vires decrescere facile ad leakage periculo.

III. Flectuntur Cracks

Finditur plerumque fieri in refrigerationem processus, maxime debitum ad nimia scelerisque accentus, mismatch de welding materiae vel ieiunium refrigerationem celeritatem post welding. Semel rimas fieri, sunt maxime difficile ad reparare, quod graviter afficit ad salutem usus.

IV. Slag inclusions

Slag inclusions sunt non-metallicis impugnant in entrrinxit in welding fis lacus, qui ex solder, fluunt, residuum vel contaminantium super superficiem aeris fistulam, afficiens vires et corrosio de Weld.

V. Pauper madefecissem

Solder deficit ad aequaliter infectum ad iuncturam superficiem, saepe quia cadmiae film super superficiem aeris tubo non purgaturus aut calefaci satis, unde in densabile solidamentum iuncturam et augendae probabilitatem in dolosus.

Imperium mensuras et processu optimization de defectibus

I. superficies preataturment-praerequisita pignus Welding Quality

In aeris evaporator tubo debet esse stricte purgandum ante welding, inter gradus, deoxidation film et siccatio. Zhejiang Jingliang aeris-tubi products Co., Ltd utitur plures preteratment processus, inter latos emundationem systems et plasma superficiem curatio, ad effective vitare pollutio in mane scaena est vitare.

II. Rationabile Electio fluxus et Solder

High-qualitas fluxus potest efficaciter removere superficiem cadmiae film et amplio welding welding. Zhejiang Jingliang uses internationally certified environmentally amica halogen-liberum flux et argentum-fundatur aut phosphor aeris-fundatur solidetur ut par in welding ratio secundum diversas fistulam et corrosio resistentia.

III. Obsecisa temperatus, imperium Welding apparatu

Welding temperatus imperium est clavem ad ne imputes et rimas. Zhejiang Jingliang introduced est intelligentes temperatus, imperium atrio, combined cum infrared temperatus mensurae et realis-vicis vigilaning technology, ad consequi precise imperium welding temperatus in range of ± V ℃, magna meliorem welding consistency.

IV. Optimize Welding Processus

Nam aeris tubulis diversis specifications, formulate personalized processus parametri (ut welding tempore, Gas fluxus, preheating tempus, etc.) et per continuam emendationem ad provectus ut talis ut pulsus brazing et laser aduenire, ut ad redigendum et defectus aduersus, significantly redigendum et laser aduenire solet.

V. Nondestructive Testing et Automated Qualis inspectionemem

Ut ut ut quisque welded aeris fistulam occurrit vexillum requisita, Zhejiang Jingliang instructa cum Abba current vitium deprehensio, X-Ray Nondestructive Testing System et pressura a welding ad complevit productum partus.

Quid pelagus gradus in productionem processus of aeris evaporator tubi?

Rudis materia praeparatio ad aeris evaporator tubo productio

In starting point of copper evaporator tube production is high-quality copper. Relying on the advantages of a complete industrial chain, Zhejiang Jingliang has its own smelting and copper material procurement channels to ensure that the purity and physical properties of raw copper meet the standard requirements. Commonly used raw materials include high-purity oxygen-free copper and specific copper alloys, which lay a solid foundation for subsequent processing.

Extrusionem CUMATIUM

In first step in the production process is the extrusion of copper. After high-temperature heating, the copper billet is extruded into a round tube billet to achieve the basic tube diameter and wall thickness specifications. Zhejiang Jingliang uses advanced extrusion equipment and a scientific temperature control system to ensure the stability of the tube billet size and surface quality, preparing for subsequent drawing processing.

Calor curatio annales

In extruded copper tube billet needs to go through the annealing process to improve the metal's organizational structure, enhance plasticity and toughness, and facilitate subsequent drawing and forming. Zhejiang Jingliang Copper-Tube Products Co., Ltd has a modern continuous annealing line that can achieve precise control of temperature and atmosphere, avoid oxidation and impurity intrusion, and ensure uniform performance of the copper tube.

Frigus drawing processus

In annealed copper tube enters the cold drawing process, and the copper tube is gradually drawn to the design specifications using a drawing machine. This process requires multiple drawing passes, combined with multiple annealing, to control the tube diameter and wall thickness accuracy. Zhejiang Jingliang uses its own high-precision drawing technology to ensure that the product has a small dimensional tolerance and high surface finish.

Imposuit et superficiem curatio

In ut ulterius amplio dimensional accurate et superficiem qualis, in aeris evaporator fistulam subit a perfectis processus. Hoc gradum accommodat exterior diameter et murum crassitudine tubi per multi-volumen urgeat. Et subsequent superficiem curatio vestigia includit Purgato, degreasing, rubigo remotionem et siccatio ut tubo est a oleum et cadmiae layer, providente mundus superficiem ad Welding et subsequent mundum.

Internum costa (internum filum) processus

In heat exchange efficiency of copper evaporator tubes depends largely on the structure of the inner surface. The internal rib copper tubes produced by Zhejiang Jingliang adopt advanced internal thread forming technology to form a regular thread structure on the inner wall of the tube, increase the heat exchange area and improve the flow state of the refrigerant, thereby significantly improving the evaporation efficiency and system performance.

Welding et Connection Processing

Quidam aeris evaporator fistulas opus est ut non ablata aut attrahunt cum aliis accessiones. Zhejiang Jingliang instructum est intelligentes Welding apparatu et stricte processus signa ut firmum et reliable welding qualitas et vitare lacus et structural defectus. Eius intelligentes vestibulum ratio monitors Welding parametri in realem tempus ut per welding saltum rate cuiusque aeris fistulam.

Quality inspection

Zhejiang Jingliang implements plena processus qualitas imperium, a rudis materia inspectionem, mole inspectionem, non-perniciosius probatio ad pressura temptationis. Praesertim ad aer emendat et pressura resistentia evapurator fistularum, in turma utitur provectus aqua pressura temptationis, aer emendationes temptationis et Abba Current Current Deprehensio apparatu et Customer Current Current Signa et elit elit.

Packaging et Warehousing

In copper evaporator tubes that have passed strict inspection enter the packaging stage, and use moisture-proof and shock-proof professional packaging materials to ensure that they are not damaged during transportation. Zhejiang Jingliang is located in Tangpu Town, the "Hometown of Copper Tubes in East China", adjacent to Shangsan Expressway and National Highway 104, and only about 70 kilometers away from Hangzhou and Ningbo. The logistics and transportation are fast and convenient, effectively supporting the timely delivery of customers across the country and even around the world.